Dec 02, 2022

The global stainless steel industry is currently characterised by deteriorating market sentiment, rising dealer inventory levels and inflationary pressures reducing consumer spending power.

Many major steelmakers expect challenging market conditions in the fourth quarter. As a result, MEPS lowered its 2022 stainless steel production forecast to 56.5 million tonnes (it had previously forecast global crude stainless steel production to reach 58.6 million tonnes this year). Total production is expected to rebound to 60 million tonnes by 2023.

Worldstainless, the body that represents the global stainless steel industry, expects consumption to recover next year. However, energy costs, developments in the war in Ukraine and government measures to combat inflation present significant risks to the forecast.

Major European stainless steel plants began cutting production in mid-2022 as energy costs soared. This trend is expected to continue in the last three months of the year. Demand from local dealers is weak.

When the war in Ukraine broke out, supply concerns led Stockholders to place large orders. Their inventory is bloated now. In addition, end-user consumption is falling. Eurozone purchasing managers' indices for manufacturing and construction are currently below 50. The data suggest that activity in these areas is declining.

European producers are still struggling with higher electricity bills. Regional sheet mills have tried to introduce an energy surcharge to recover these costs, but local buyers have refused. As a result, domestic steelmakers are cutting production to avoid unprofitable sales.

Us market participants were more positive about the economic outlook than their European counterparts. Yet underlying domestic steel demand is falling. The availability of materials is good. Production is expected to decline in the fourth quarter to meet current market demand.

Asia

Chinese steel production is expected to decline in the second half of the year. The epidemic is affecting domestic manufacturing activity. Expectations that domestic steel consumption would increase after the Golden Week holiday proved unfounded. Moreover, despite the recent announcement of fiscal measures to support China's property sector, underlying demand remains weak. As a result, melting activity is expected to decrease in the fourth quarter.

In South Korea, melting figures for the July/September period are expected to be lower month-on-month due to weather damage to POSCO's steel mills. Despite plans to quickly bring these facilities back online, production in South Korea is unlikely to recover significantly until later this year.

Smelting activity in Taiwan has been hampered by high inventories on the island and sluggish end-user demand. By contrast, Japan's output is expected to remain relatively stable. Steel mills in the country reported steady consumption from local customers and were likely to maintain current production.

Indonesian steel manufacturing is estimated to have declined month-on-month in the July/September period. Market participants report a shortage of nickel pig iron, the main raw material for the country's stainless steel production. In addition, demand in Southeast Asia is sluggish.

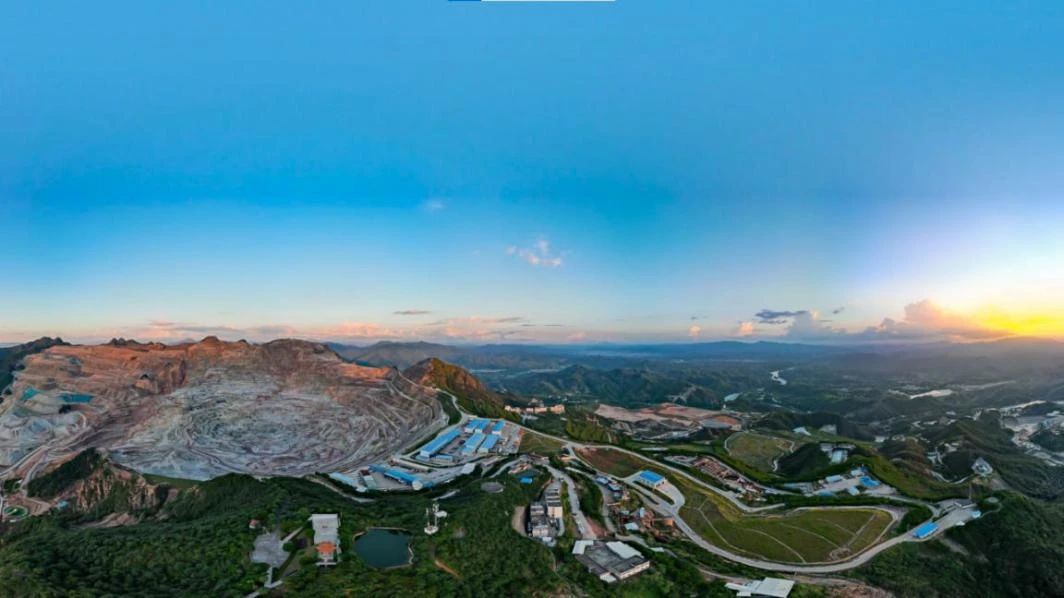

Previous:Vale And Huayou Cobalt Have Launched A Large Nickel Project in Indonesia

Next:PTAKP Expects A 40% Increase in Nickel Production By 2023