Dec 16, 2021

"BHP billiton expects nickel demand in the battery industry to surge by more than 500 per cent over the next decade. With the goal set by the Paris Climate Agreement of no more than 1.5 degrees Celsius of global warming compared to pre-industrial levels, we expect nickel resource demand to quadruple over the next 30 years compared to production over the last 30 years." Vandita Pant, BHP billiton's chief commercial officer, predicted on Dec. 14 at an industry forum in Tianjin, China.

BHP billiton is one of the world's largest suppliers of metal commodities, including nickel, an important metal material for new energy vehicles. Commodities like nickel are crucial to a sustainable energy transition, Pan said. About 85 per cent of BHP's nickel is now used globally to make battery materials for electric vehicles, up from about 21 per cent in 2017 and less than 5 per cent in previous years.

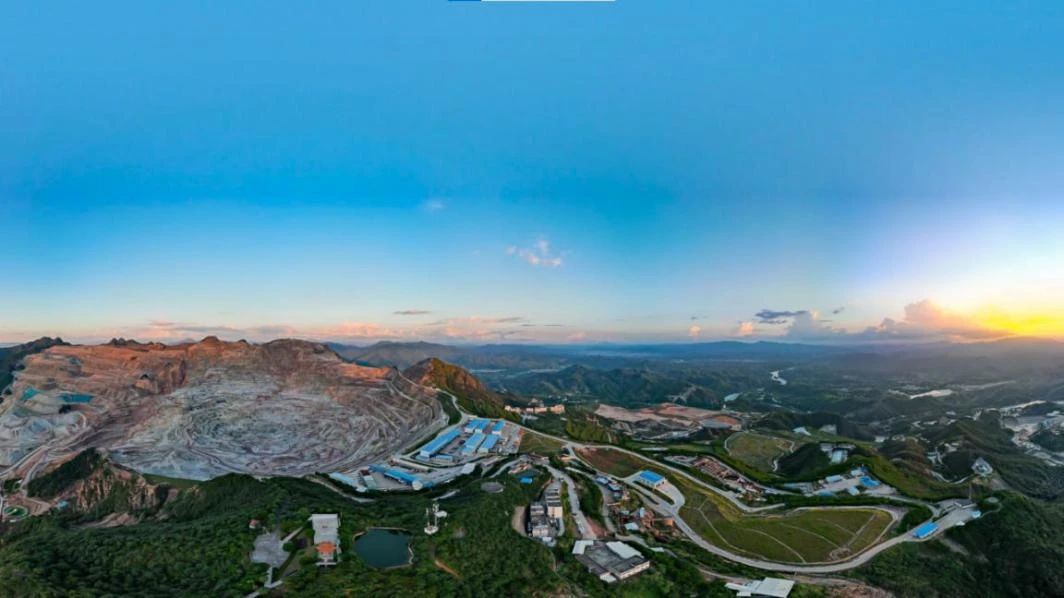

Behind this change is a concerted global move towards carbon neutrality and the resulting acceleration of the electrification of new energy vehicles. BHP billiton believes that China's new energy vehicle industry is developing rapidly, and a huge new energy vehicle market contains huge business opportunities. China is the world's largest market for neVs and is home to the world's leading battery makers. In line with current trends, it will be crucial to ensure a reliable and sustainable supply of raw materials such as nickel for power battery production.

Relevant data show that in 2020, the world will use 2.48 million tons of nickel, and China will demand 1.4 million tons of nickel. In 2020, the global nickel consumption in the power battery field is about 107,000 tons of nickel metal, accounting for about 5%. Most research institutions believe that the global nickel demand for power batteries will increase significantly in the next decade, as will the proportion of the total nickel consumption.

In addition to nickel, cobalt and lithium are the key metal raw materials of new energy vehicle batteries, but the uniformity of these battery raw materials depends on progress. On the same day, the forum released a research report on the prospect of electric cars in China. The report shows that lithium resources are limited by many factors, such as technology level and development conditions, and the domestic development degree is low, with the amount of lithium ore taking 80%. Domestic cobalt resources are poor, mainly rely on the continent into; Nickel resources only account for 3% of the world's total, the domestic production is far lower than the demand, more external dependence; Low carbon efficiency development of the industrial chain is of great significance to carbon emission reduction standards, and sustainable raw material supply is an important development trend in the future.

根据上述研究报告,安装led structure of automotive battery presents energy density and low "polarization" development, and the installed share of 140Wh/kg and lower and 160Wh/kg and above increases significantly. Among them, the line of lithium iron phosphate "strong return", share by 32% rise 38%. The crystal structure of lithium iron phosphate material is more stable, the theoretical life is more, and it is not easy to release oxygen reaction, and the material is intrinsically safer than another battery technology route -- ternary battery (nickel, cobalt, lithium) material.

However, ternary batteries have intrinsic advantages, and the upper limit of theoretical energy density is higher at present. Power performance of ternary materials: electrical conductivity, ionization diffusion coefficient, theoretical true density, vibration real density. Ternary materials are relatively expensive due to the scarcity of nickel and cobalt, but the development of "low cobalt" and "cobalt" battery technology and the improvement of energy density provide more possibilities for the progress and cost reduction of ternary batteries.

The report believes that teranyuan and lithium iron phosphate batteries have their own advantages in performance, cost and safety, and new energy vehicle industry chain enterprises need to make positioning planning according to market demand to provide more options.