Dec 23, 2021

BHP billiton: Primary nickel demand is expected to grow by 1.3 million tonnes over the next 10 years.

"Over the next decade, electrification will be the trend." On December 14, BHP Billiton metals and mining market analysis director Wenjun Bao at the 2021 Energy saving and new Energy vehicle development Report release.

Bao further said that looking back on last year, the ev market has ushered in a new explosion in 2020, with global sales reaching 3.2 million units, up 44% from 2019, and the penetration rate of global light vehicle sales reaching 4.3%. This strong increase has continued this year and is showing signs of accelerating. "Looking ahead, we believe there are many favorable factors for the industry's development, as governments around the world have recently announced long-term goals for the adoption of electric vehicles and rolled out supportive policies." Bao wenjun said.

The rapid development of electric vehicles is driving nickel demand

Bao believes that today's consumers, especially the younger generation in cities, are more interested in environmentally friendly electric vehicles. All of these factors lead us to believe that global electric vehicle sales will grow rapidly. We predict that global electric vehicles, which we call pure electric + plug-in, will account for as much as a quarter of global light vehicle sales by 2030, and the penetration rate will be even higher in leading electric markets like China and Europe.

The rapid development of electric vehicles will inevitably drive the development of the battery industry. There are different kinds of batteries used in electric cars, and it is reported that ternary lithium batteries are one of the mainstream technologies. The cathode of a three-way battery uses three different elements, nickel, cobalt, and a third metal, either manganese or aluminum. Among these elements, nickel is very important to improve the energy density of batteries and the endurance of electric vehicles. Generally, nickel is the largest proportion of three cathode materials.

Bao believes that the future of battery technology will present two major trends: the first trend, the ternary battery industry is the long-term mainstream. In 2020, lithium nickel-cobalt-manganate batteries, lithium nickel-cobalt-aluminate batteries and lithium iron phosphate batteries are the main types of power batteries for passenger vehicles worldwide, and nickel-containing batteries account for more than 80%. In the long term, nickel-containing ternary batteries have greater space for improvement in energy density and more development potential, so ternary batteries will become the main technical route of global passenger car power batteries. The second trend is that nickel-containing batteries themselves are also improving. This progress is reflected in the continuous increase of nickel content. Ternary batteries in this diagram can be divided into two categories, one is nickel-cobalt-manganese lithium battery, and nickel-cobalt-aluminate lithium battery. Among the three cathode materials, the proportion of nickel in some products has reached 80%, and more nickel batteries in the future.

Bao believes that with the increase of nickel content, the energy density of the three-way battery will increase, and the cost per unit of energy will decrease, and then become more competitive in cost. At the same time, the improvement of energy density and battery performance can relieve consumers' range anxiety and help improve the performance of electric vehicles. "So we expect the demand for nickel for batteries to grow exponentially over the next decade." Bao wenjun said.

Currently, the vast majority of nickel in the market is actually used in non-battery industries. In 2020, only 5% of primary nickel will be used in batteries, while the vast majority of the rest will be used in stainless steel. Stainless steel currently accounts for two-thirds of the world's nickel use. "Nickel in the battery industry, although currently from a small base, will be a major growth driver in the future. "We expect total nickel demand to grow at a compound growth rate of 5 percent over the next decade, but nickel demand for batteries will grow at a rate of over 20 percent." "The market demand for primary nickel will increase by about 1.3 million tons in the next 10 years. The battery industry, although from a small base, can contribute more than half of the increase, or about 700,000 tons. "By 2030 we think the battery industry will account for more than 20% of the world's primary nickel demand."

In terms of nickel supply, nickel ores are widely distributed and of different types worldwide. It can be roughly divided into two types, the first is nickel sulfide ore, and the second is oxide ore (commonly known as laterite nickel ore). Nickel sulfide ore mining history is long in history, in the past century it has been a traditional main source of nickel, nickel sulfide ore after flotation gold nickel content is higher, is also conducive to further refine, nickel sulfide ore distribution, are mainly distributed in the high latitudes, Russia, Canada, northwest China's gansu jinchuan, and South Africa, Australia. The global sulfide ore resources are relatively limited, and the increase of nickel ore in the last 20 years mainly comes from laterite nickel ore. Laterite nickel ore is geographically distributed in tropical areas along the equator, and laterite nickel ore is especially suitable for the production of nickel pig iron or nickel-iron alloy because of its high iron content. In terms of final use, laterite nickel ore is mainly used in stainless steel manufacturing. In the past decade, with the rapid development of stainless steel industry in China, Southeast Asia, Indonesia and the Philippines have become the main suppliers of laterite nickel ore in the world.

BHP billiton is committed to achieving low carbon emissions in nickel production

前镍矿可以转化为镍,can be used in batteries, it has to go through the intermediate, nickel sulfate. Western Nickel, a unit of BHP billiton, produces grade 1 nickel through sulphide ore. More recently, some nickel suppliers have explored, for example, reprocessing nickel pig iron for the battery industry to open up the path of laterite nickel for battery applications.

BHP billiton previously supplied the finished products on the market mainly nickel beans and nickel powder. However, we have recently invested in downstream nickel sulphate processing facilities. While constantly increasing the proportion of products sold to batteries, we are also changing the form of end products to get closer to our battery industry chain.

BHP's new nickel sulphate plant will have a capacity of more than 100, 000 tonnes a year once it reaches production, making it one of the largest nickel sulphate projects in the world. Its latest shipment of nickel sulphate has begun shipping to China for customers in the downstream industry chain.

Although electric cars themselves are much more low-carbon than petroleum-based vehicles, BHP billiton is still exploring ways to make batteries or the raw materials for batteries as low-carbon as possible to reduce its carbon footprint. "Since a lot of CARBON dioxide is generated from nickel, cobalt and lithium mining, smelting and final battery pack production, it is necessary to produce battery raw materials and batteries in a greener way in order to reduce the carbon footprint of the value chain and industry chain, and take into account the proportion of the total emissions of batteries." Bao wenjun said.

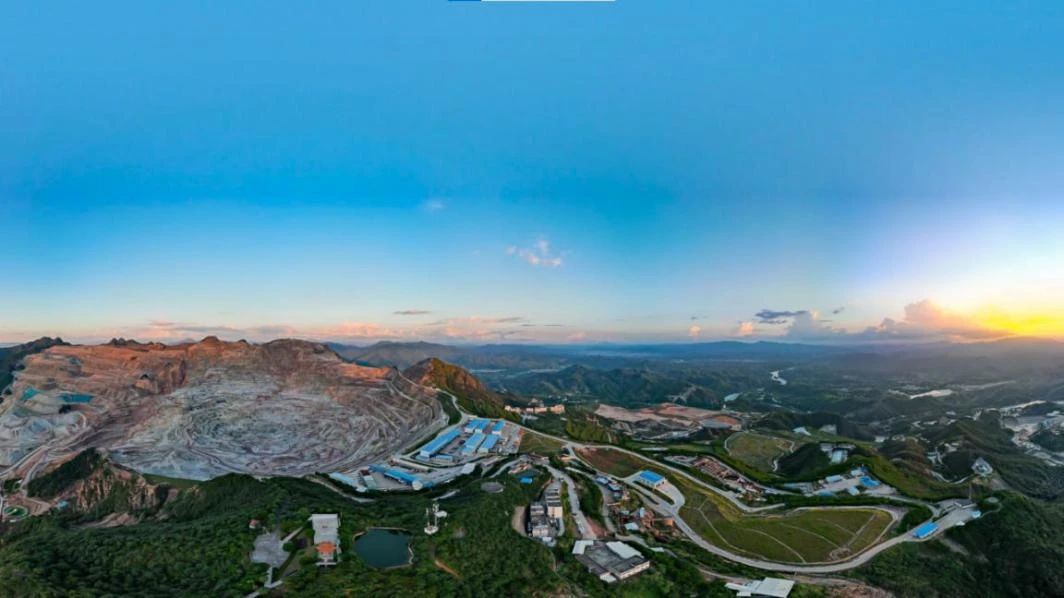

Bao told reporters that since nickel mining, dressing and smelting use a lot of electricity, their first step was to start sourcing renewable energy such as solar power. In February, BHP announced a purchase agreement for 20 megawatts from local solar plants, and recently added another 30 megawatts. In addition to outsourcing solar energy, BHP is also building its own farms and energy storage systems, and will next explore the possibility of wind power.

Mr Bao highlighted the increasing use of electric vehicles in nickel mines both above and below ground. "Because the nickel we produce goes to electric vehicles, and in turn those green electric vehicles end up in our mines, forming a true closed loop. All of these moves are aimed at more sustainable development."

Previous:Tin Is The Target Of Expansion At SAN Bartolomei

Next:Vedanta Resources Of India Bought Nicomet, The Country's Nickel Sulphate Producer